Understanding the building materials and structure of real estate can help you choose a more suitable property.

Have you ever considered knowing more about the construction materials and structure of the real estate when considering buying a property, ? Whether you're buying property as an investment or for your own use, understanding the building materials and structure of real estate can help you choose a more suitable property.

In your daily life, do you ever pay attention to the materials or methods used in the things around you? You might not care how a dress or shirt is tailored, but you may care about the material of it. Similarly, when buying furniture, you may not be interested in its manufacturing process, but you might value whether it's made of wood, plastic, or something else. However, when considering purchasing a property, have you ever considered knowing more about the construction materials and structure of the real estate? Whether you're buying property as an investment or for your own use, understanding the building materials and structure of real estate can help you choose a more suitable property.

This article will elaborate on the characteristics, advantages, and disadvantages of the main building materials and structures in Japan, so you can understand more about Japanese real estate structures.

The following are the four main types of building materials and structures in Japan:

-

(1) Wood Construction

-

(2) S Construction (Steel Frame Structure)

-

(3) RC Construction (Reinforced Concrete Structure)

-

(4) SRC Construction (Steel Reinforced Concrete Structure)

Let’s have a look at each type of the above construction in Japan.

(1) Wood Construction

Wood construction is the most common way to construct houses in Japan. Timbers are used as the structural framework for houses. Most of the timbers are from fir trees or hinoki trees. Due to the relatively low cost of wood (as compared with other materials) and the simplicity of the construction process, about 70% of detached houses in Japan are constructed of wood. The method of wood construction already has a long history in Japan, and the Japanese are renowned for building high-quality wooden housing designed to withstand earthquakes and other natural disasters. Recently, major construction companies in Japan like SUMITOMO FORESTRY CO., LTD. have announced plans to build high-rise buildings primarily using timber as the main material by 2041, further highlighting the importance of wood construction.

Based on the structural framework, there are two main methods of wood construction.

■ Post and Beam Construction Method:

It is a derivative of classic timber frame construction. It uses vertical structures (named "posts") and horizontal structures (named "beams") to create a framework that allows for expansive flooring and flexible structuring.

Posts and beams support the weight and incorporate elements like shear walls and diagonal braces to withstand natural disasters like earthquakes and typhoons. Many wooden detached houses in Japan are built using this method.

■ 2x4 Construction Method:

This method was introduced in the United States and primarily utilizes angled lumber frames, supplemented with plywood, to create floors and walls. The name "2x4" comes from the dimensions of the lumber used, 2 inches by 4 inches, as this is the most cost-effective size of lumber and has been used for many years in the housing industry. The construction process is relatively simple compared to post and beam construction, but creating open interior spaces can be more challenging due to the flat structure.

Advantages and disadvantages of wood construction:

■ Advantages:

○ Lower Cost: Wood is relatively inexpensive and easy to work with.

○ Humidity Adjustment: Wood can absorb and release moisture from the air, helping maintain comfortable indoor humidity levels.

△ Energy Efficiency: Energy efficiency is improved by using modern high-insulation and high-density materials for wood construction.

■ Disadvantages:

△ Vulnerability to Vibrations: Wood is a lightweight material and is susceptible to vibrations.

△ Sound Insulation: As wood lacks sound insulation properties, it can allow sound to transmit easily.

△ Fire Resistance: Wood is inherently flammable, making it less fire-resistant.

△ Durability: Wood can be susceptible to factors like pests and mold, leading to a relatively shorter lifespan.

(2) S Construction (Steel Frame Structure):

S Construction, also known as Steel Frame Structure, is a type of building structure that uses steel materials for vertical columns and horizontal beams as the structural framework. They are riveted, bolted, or welded together in a rectilinear grid. Steel beams are horizontal structural members that resist loads applied laterally to their axis, while columns are vertical structural members that transfer compressive loads. It can be used to form the skeleton of a building.

Because steel is relatively lightweight, strong, and flexible, it is well-suited for buildings with larger spaces, such as high-rise buildings, sports arenas, and office buildings that require fewer interior columns.

Steel frame structures can be categorized into "lightweight steel frames" and "heavyweight steel frames" based on the thickness of the steel material. Lightweight steel frames are made from thin steel, while heavyweight steel frames use thick steel. Additionally, lightweight steel frame structures can be prefabricated in factories and assembled on-site, making construction simpler and more cost-effective.

■ The Advantages of S Construction include the following:

-

○ Lower Cost: By using lightweight steel frame structures, construction costs can be reduced.

○ Flexible Space Creation: The hardness and flexibility of steel allow for the creation of spacious interiors with smaller columns and other components.

○ Thermal insulation and energy efficiency: Using high-performance insulation materials on roofs and exterior walls can increase the efficiency of HVAC systems (Heating, Ventilation, and Air Conditioning Systems), leading to energy savings.

■ The Disadvantages of S Construction include:

△ Vulnerability to Vibrations: Steel, being a lightweight material, is susceptible to vibrations.

△ Sound Insulation: Sound insulation may be weaker depending on the building materials used for interior walls.

△ Fire Resistance: Steel is sensitive to high temperatures and may have poorer fire resistance. While fire-resistant coatings can be applied to walls, it might increase costs.

△ Durability: Steel can be susceptible to corrosion, affecting its durability. Although rust-resistant coating can be used to improve longevity, it can also add to the costs.

(3) RC Construction (Reinforced Concrete Structure):

RC construction, or reinforced concrete structure, is a building construction method primarily based on concrete and reinforced with steel. Concrete is produced from a mixture of cement, sand, gravel, and water through a process known as the hydration reaction. It can be formed into different shapes during its liquid state, which makes it the most widely used construction material in the world.

Although concrete is good at compression, it is weak at tension. In this regard, steel reinforcement is usually introduced to take up the tensile stresses of concrete. The structure that is made up of steel reinforcement embedded in concrete to form a load-resisting composite is known as a reinforced concrete structure, which is an excellent structural material.

While steel may be susceptible to rust and corrosion, the presence of durable concrete protection enhances the overall structural integrity. Reinforced concrete structures offer superior fire resistance, durability, sound insulation, and thermal insulation properties, making them suitable for mid-rise residential buildings.

■ The Advantages of RC construction include the following:

○ Sound Insulation: Thick concrete walls and floors effectively block noise from neighbors and reduce vibrations from movement.

○ Thermal Insulation: The building materials of reinforced concrete provide excellent thermal insulation, reducing heat transfer from the outside.

○ Energy Efficiency: RC construction with sealed roofs and walls enhances energy efficiency, leading to energy savings.

○ Fire Resistance: Concrete's inherent fire resistance properties do not require additional treatments and provide high fire resistance.

○ Durability: Concrete is a corrosion-resistant material with excellent durability, reducing the need for frequent maintenance.

■ However, RC Construction also has some disadvantages:

-

△ Poor Ventilation: While the high level of sealing is an advantage, it can lead to issues such as frost and mold growth, particularly in poorly ventilated areas.

△ Space Constraints: As concrete is relatively heavy, more walls and columns are required to support the interior structure, making it challenging to create spacious and open column-free interior spaces.

(4) SRC Construction (Steel Reinforced Concrete Structure):

SRC Construction, or Steel Reinforced Concrete Structure, is a building construction method that embeds a steel frame within the components of a reinforced concrete structure. This approach combines the strength of reinforced concrete structures with the flexibility of steel frame structures. Since steel rods are inserted into the concrete before it becomes hardened, it can hold the concrete together and prevent large cracks. Steel reinforcement adds overall strength, which allows for the creation of longer, thinner, cantilevered structures. With its ability to create large spaces and enhance seismic resistance, it is often used in large-scale buildings such as high-rise skyscrapers and infrastructure like bridges and transport hubs.

However, because it requires materials like steel rods, steel frames, and concrete, the construction cost of SRC is relatively high, and the construction process can be complex and time-consuming.

■ The advantages of SRC construction:

Because it combines the characteristics of both RC (Reinforced Concrete) structure and S structure, it simultaneously enjoys the following benefits.

○ Sound Insulation: Like RC construction, thick concrete walls and floors effectively block noise from neighbors and reduce vibrations from movement.

○ Thermal Insulation: Both RC and S Constructions offer good thermal insulation, and SRC, combining their features, can achieve even better thermal insulation, reducing the transfer of heat from outside.

○ Fire Resistance: While S Construction has limited fire resistance, the presence of steel rods within the reinforced concrete of SRC enhances its fire resistance.

○ Durability: Concrete is a corrosion-resistant material, providing excellent durability and reducing the need for frequent maintenance.

○ Seismic Resistance: By combining the features of RC and S structures, the ability to resist seismicity has been further enhanced. With higher strength and flexibility, it could further withstand earthquakes and other natural disasters.

■ Disadvantages of SRC Construction:

-

△ Higher Cost: The use of multiple materials such as steel rods, steel frames, and concrete, along with the complexity of integrating steel into the RC structure, significantly increases construction costs.

△ Poor Ventilation: Similar to RC Construction, the high-density and sealing properties of concrete can lead to poor ventilation, potentially causing issues like frost and mold growth, especially in poorly ventilated areas.

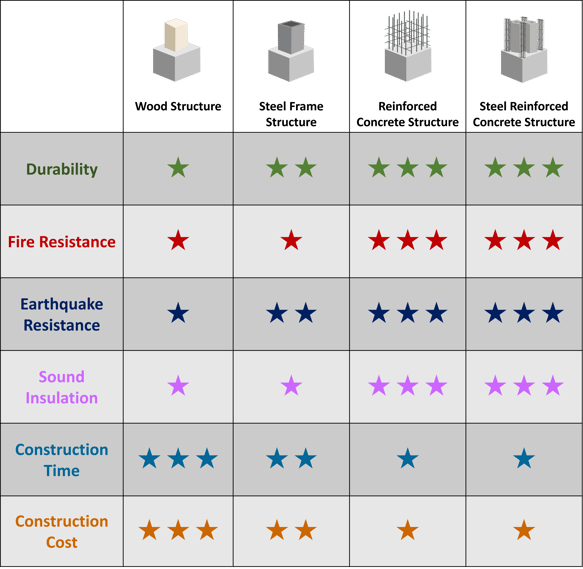

The following table shows a comparison of the four building structures to make it easier to understand their respective characteristics:

The above has explained the basic information about the four main building structures in Japanese architecture, along with their respective advantages and disadvantages. It is hoped that this will help understanding more about real estate in Japan. As each type of structure has its strengths and weaknesses, it is important to consider your own needs and make the right choice when purchasing real estate.

※Please note that the above content is for reference only, as it just provides a general overview based on typical situations. Building conditions can vary significantly between different properties, so it is not advisable to generalize based solely on the information presented above.

If you would like to learn more about property investment in Japan, please click here. >

You might have interest to read the following articles as well:

○ What is the tendency of Land Price in Japan in 2023?

○ 2022 Tokyo Autumn Leaves | 10 Fantastic Fall Foliage Sceneries in Tokyo

○ A guide for foreigners buying real estate in Japan.

○ What is the most updated land value in Tokyo and the changes in 5 years ?

○ NEW OR OLD? Which one is better for property investment in Japan?

○ What are the costs incurred when buying a property in Japan?.

○ What is 1R, 1K, 1DK and 1LDK?

(REF: B-MN-E01